Building on the sonic performance of the DG-1, we’ve boosted the sound quality without sacrificing the musicality that the DG-1 was revered for. Improvements include higher resolution replay, greater dynamic contrasts, and improved stereo separation with greater precision.

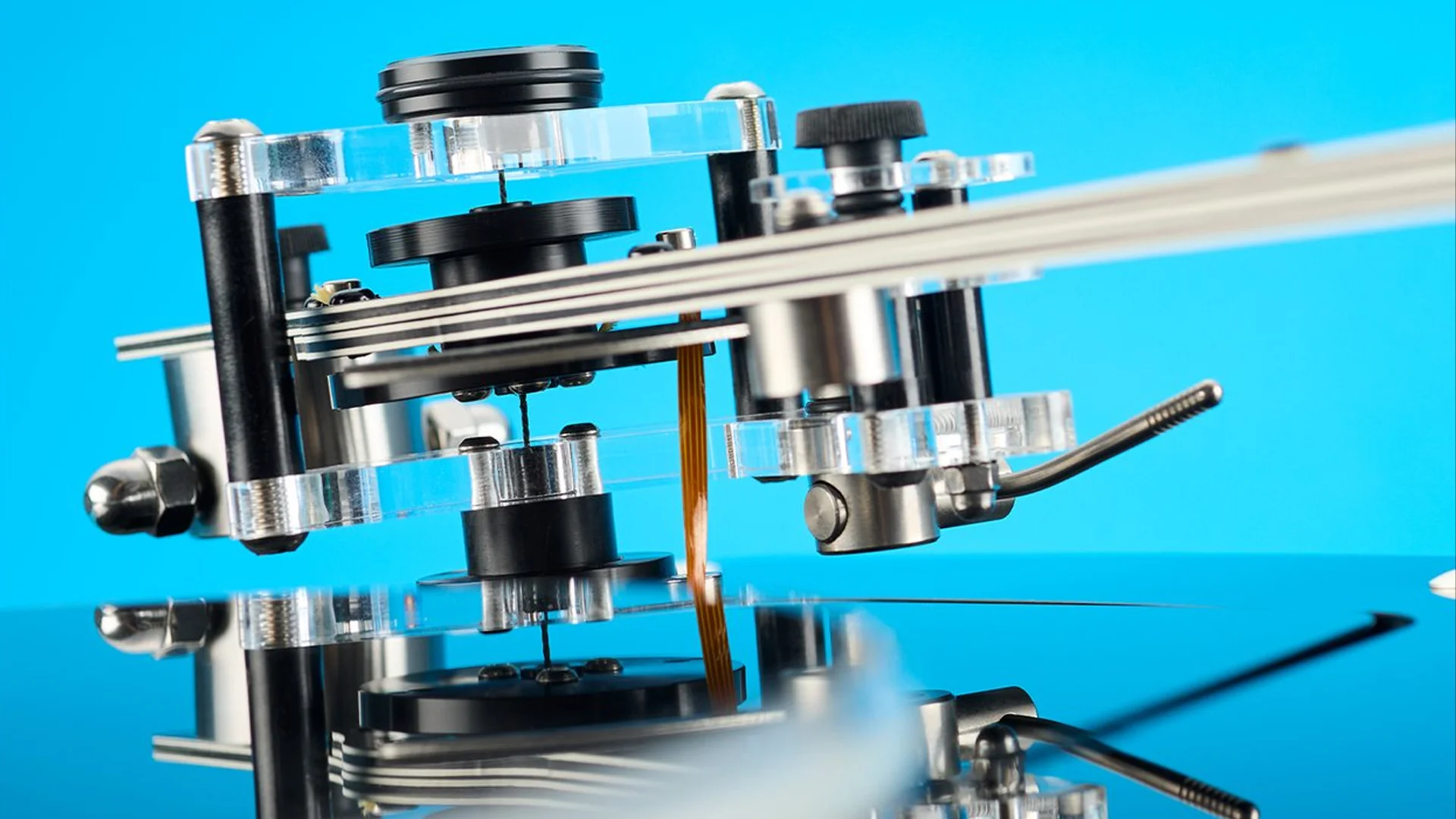

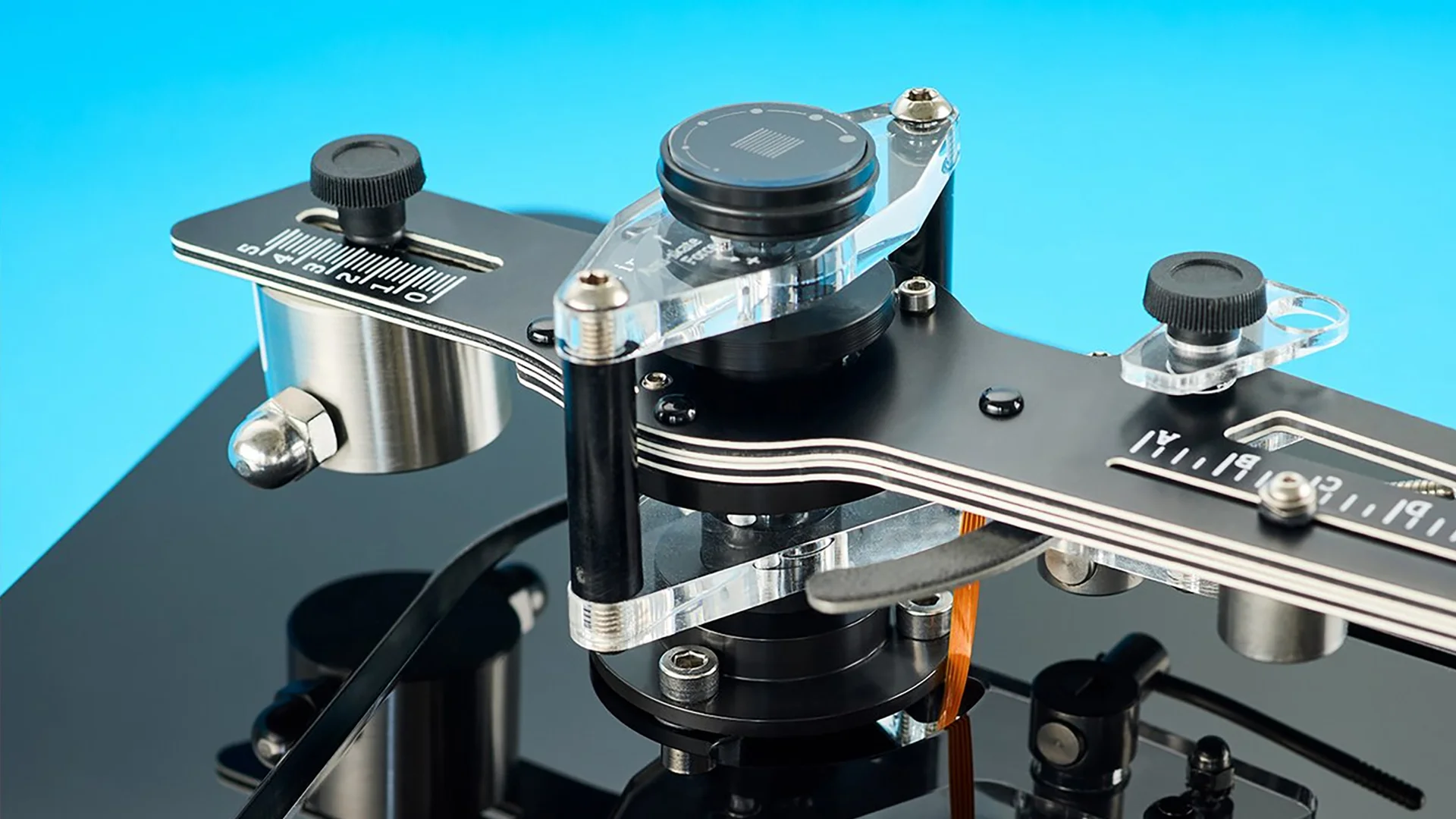

New 5-ply tonearm beam

New 5-ply Groove Runner S Top and Lower beams possess much higher acoustic linearity than their predecessor.

Top and Lower beams are bonded and riveted to ensure optimum rigidity combined with linear resistive damping.

Couple the above with the inherent critical damping of the beam construction and we have an ideal platform to support the cartridge.

Improved tonearm bearings

Groove Runner S Kevlar thread bearing is now adjustable for tension and azimuth. With the new Azimuth Adjustment Counterweight Screw, finer azimuth setting is made easier and more accurately to enhance cartridge performance.

New higher tolerance super polished main bearing spindle

DG-1S utilises a higher tolerance matched main bearing with super polished bearing spindle for ultra-smooth, noise-free running. The new bearing ensures even quieter background further enhancing dynamic range and resolution.

New Motor Drive software

The new motor drive software facilitates a three step factory adjustment of the motor torque and noise setting with a final minimum noise adjustment. The new software allows an initial setting of the sine wave voltage and fixes it to establish the reference. A separate, independent cosine wave voltage setting with phase angle adjustment ensures lowest noise and vibration from the drive motor.

Specification

Type

Belt drive

Motor

24 Pole Synchronous

Acetal Spindle Thrust Bearing

Motor Mount

Axially De-coupled

Pulley

Super Precision Aluminium Alloy

Drive Belt

Bespoke Silicone Rubber

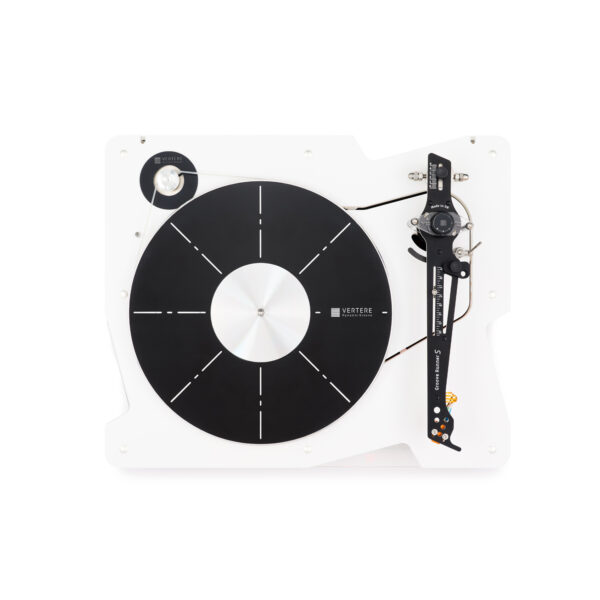

Platter DG-1

Precision Machined Aluminium Alloy

PETG Bonded Record Interface Mat

Underside Bonded Resonance Control Disc and Bonded Protective Cork/Neoprene/Nitrile Disc

Bearing Spindle DG-1

Non Magnetic Stainless Steel

Super Precision Machined and Polished

Roundness / Concentricity

< 5 Microns

Bearing Housing

Brass

Super Precision Machined

Bore Tolerance < 5 Microns

Super Precision Tungsten Carbide Ball

Plinth Structure

3 Layer Cast Acrylic

Middle Clear Plinth, Internally Illuminated

Isolation System

6 Point, Bespoke Silicone Rubber

Support Structure

Black Coated Zintec Steel Chassis

Three Adjustable Feet with Resistive Felt

Motor Drive

Advanced Microprocessor Controlled

Fully Programmable with Motor Noise Reduction

Bridged Balanced Motor Output Amplifiers

Speeds

33.3 and 45 rpm (+/- 0.2%)

Electronically Selectable

Dust Cover

Bespoke Formed Tinted Polycarbonate

Dimensions (W x D x H)

469 x 384 x 130mm (including dust cover)

Power Supply

Wall Adaptor Type

UK, US, EU and AUS Exchangeable Plugs

100 – 240 Vac with 1.5m Cord

Finishes

Black and white gloss

Weights

8kg – Net