DEVELOPED THROUGH 30+

YEARS OF ITERATIVE DESIGN &

DEVELOPMENT.

A WILSON BENESCH CLASSIC.

A.C.T. – ‘Advanced Composite Technology’ refers to the composite technologies upon which the Wilson Benesch brand was founded and has subsequently become synonymous. The A.C.T. acronym was used in 1991 for the company’s first loudspeaker, the A.C.T. One, which set several benchmarks, including being the world’s first carbon fibre composite loudspeaker ever produced.

A.C.T. technology has been used through four successive designs, arriving today at the A.C.T. 3Zero the sixth generation A.C.T. loudspeaker. The A.C.T. 3zero, therefore, follows a long line of speakers, embodying the heritage of the Wilson Benesch brand and the classic A.C.T. design.

Similar physical proportions have been retained, however, the A.C.T. 3Zero marks a significant departure from the use of carbon fibre composite materials in the monocoque that forms the loudspeaker enclosure, moving into the next generation of biocomposite materials technology. The new biocomposite A.C.T. 3Zero Monocoque is made from naturally sourced, renewable and sustainable materials and is superior in performance, being better damped and more silent than the previous generation enclosure.

The new A.C.T. 3Zero also marks the first occasion in history that an A.C.T. loudspeaker is installed with an Isobaric Drive System. The new A.C.T. 3Zero incorporates the IDS within the elegant, exquisitely engineered foot. Combined with the new Tactic 3.0 and the Fibonacci Tweeter, the A.C.T. 3zero delivers a new level of sonic performance from the A.C.T. marquee, setting the benchmark for the industry in this sector.

TACTIC 3.0 DRIVE UNIT

The structure at the centre of the diaphragm plays a critical role in the behaviour of the drive unit. Commonly referred to as the “dust cap”, the name understates the importance of this component. In the Tactic 3.0, Wilson Benesch added the Fibonacci Element.

Produced in house using additive manufacturing technology, the Fibonacci Element can be printed according to pre-designed parameters. Such is the precision of the additive manufacturing software, that the Wilson Benesch design team can see in cross-section and design three-dimensionally the optimal layup of carbon fibre and nylon, defining both stiffness and weight across the structure. The result is a new geometrical form that is comprised of a double curvature with both open and closed aspects in the form of a lattice structure again borrowed from natural geometry. 5 different materials and adhesives provide significant improvements in both the accuracy of the frequency response and the reduction of distortion.

This is a critical aspect of the relationship between the drive unit and its ability to integrate with the roll off of the tweeter and bass drive units. In the past, several materials have been drawn upon to enable the fine-tuning of this marriage. Additive Manufacturing has opened up a new chapter in the pursuit of this subtle but extremely important aspect of loudspeaker design. For the first time, the principal aspects of this structure can all be adjusted in a way that was previously impossible.

FIBONACCI SILK-CARBON HYBRID TWEETER

The latest iteration of Wilson Benesch tweeter technology builds upon the Semisphere tweeter design pushing it into the next generation. As with all Wilson Benesch designs, the advances of the previous generation are built upon an iterative research and development pathway. With the Fibonacci tweeter, advances have been made within the structures adjacent to the motor and the hybridised dome.

The Fibonacci tweeter faceplate is formed from a carbon fibre – nylon composite structure creating a geometrically optimised structure – the Fibonacci Element – that has been inspired by sacred geometry found in nature. In terms of acoustic performance, the faceplate delivers a new benchmark in terms of flat frequency response and ultra-wide dispersion. In addition, the Fibonacci Element is decoupled from the motor and tweeter chassis which almost entirely eliminates structural borne resonance within this critical structure that surrounds the tweeter dome.

A.C.T. 3ZERO BIOCOMPOSITE MONOCOQUE

The Fibonacci Series introduces a full line of loudspeakers from the Wilson Benesch brand that are built from the new A.C.T. 3Zero biocomposite Monocoque. The new monocoque marks significant advances not only in terms of the acoustic performance of the Wilson Benesch reference line, but it also represents a deliberate and conscious move toward natural, renewable and sustainable materials technology.

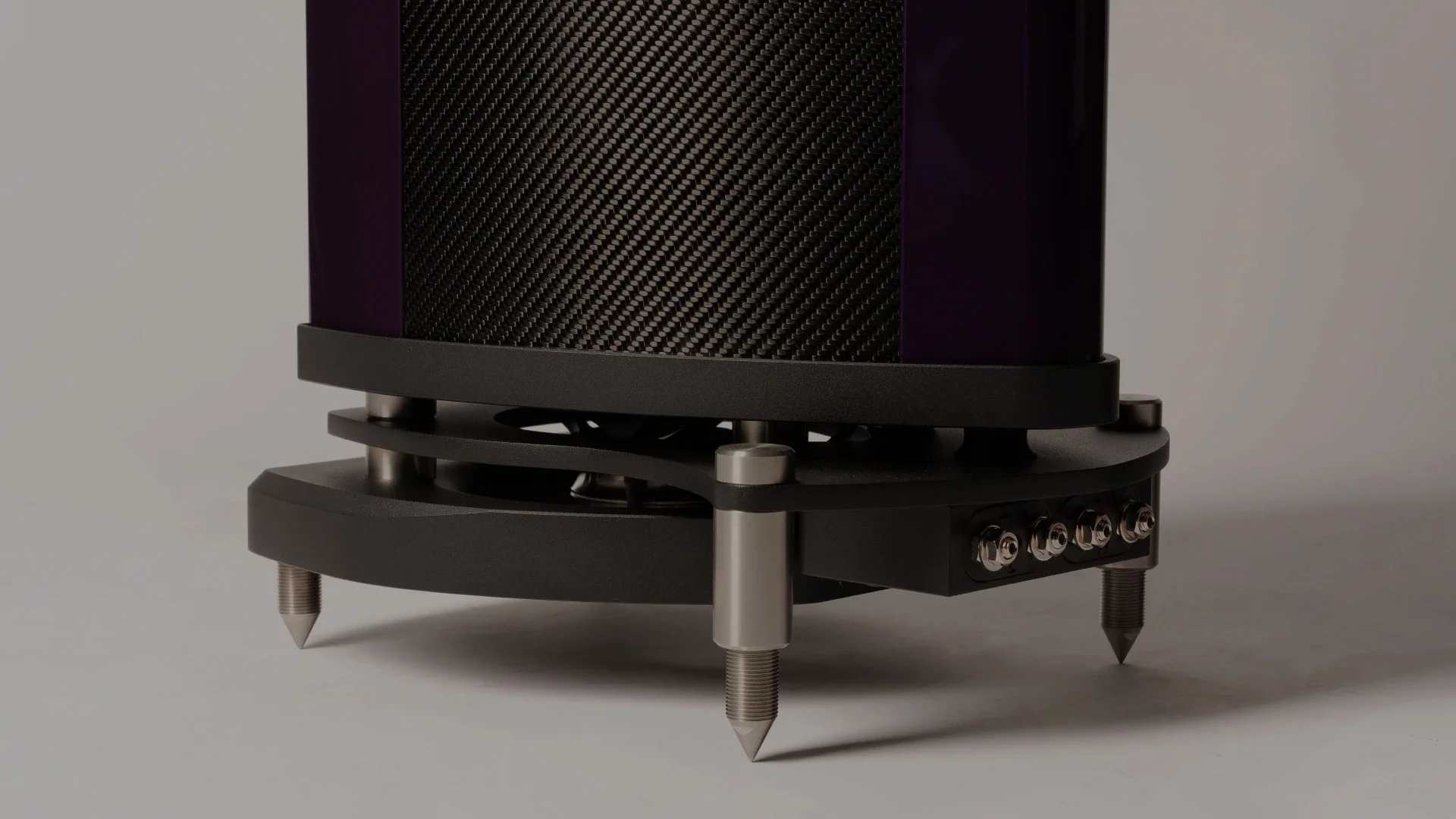

ISOBARIC DRIVE SYSTEM

The principal low-frequency load of all loudspeakers in the Fibonacci Series is delivered by the Isobaric Drive System. Here two Tactic 3.0 Drive Units combine to create an Isobaric Drive System. The Isotactic Drive System is responsible for reproducing an incredibly tight and controlled bass response that is perfectly integrated with all other woofers in the loudspeaker chassis, particularly the midrange Tactic 3.0 drive unit.

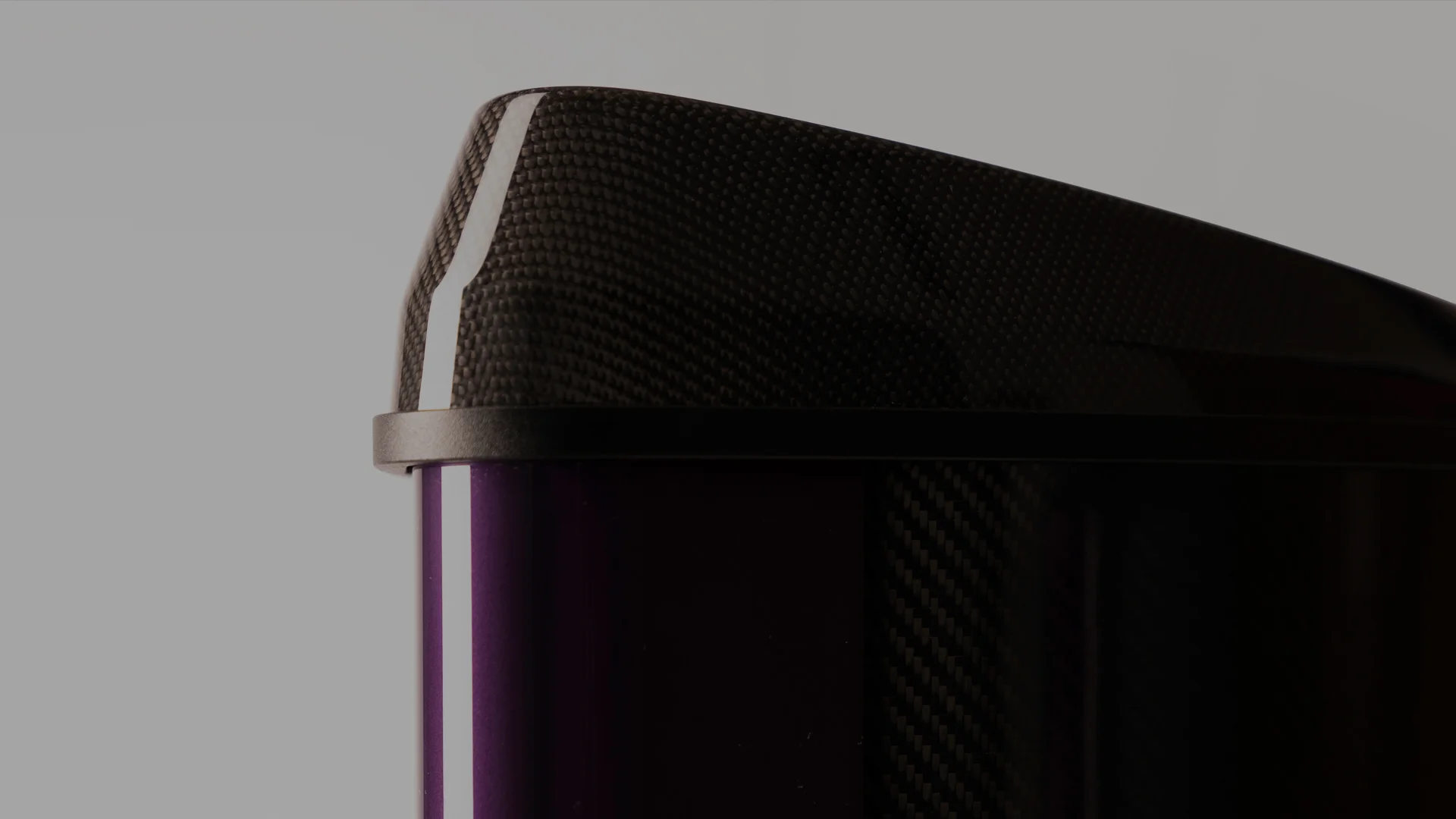

CARBON FIBRE COMPOSITE STEALTH TOP

Wilson Benesch fit a beautifully sculptural carbon fibre composite top to its reference line loudspeakers. The forms are inspired by natural, organic shapes, curves and free flowing lines found in nature.

The carbon fibre tops are extremely complex forms are created using a combination of hand sculpting in clay which are in turn measured using a laser and in turn loaded into advanced 3D digital computer aided design (CAD) software at Wilson Benesch. By importing data in this way, Wilson Benesch are able to use powerful software algorithms to further optimise the 3D form before manufacturing.

When a longitudinal sound wave strikes a flat surface, sound is reflected in a coherent manner. However, the reflective nature of a structure varies according to the shape of the surface. Uneven surfaces will diffract sound wave energy, rather than reflect it directly with little reduction in the energy of the sound wave which it perceived as colouration in the HIFI system. Therefore the complex ‘stealth like’ form is critical to the performance of the loudspeaker. By removing any flat, reflective surfaces and creating a highly complex structure, any reflective sound energy is scattered. This diminishes its energy and also avoids standing wave patterns within the listening space that are easily detected by the human ear as distortion or colouration.

DIRECT MIDRANGE DRIVE UNIT COUPLING

Wilson Benesch started development of its own drive unit diaphragms, including those made from a carbon fibre/epoxy matrix in 1995. Research was conducted using alternative hard dome materials. Without exception, Isotactic Polypropylene was favoured for its natural sound and the ability of this material to absorb energy and avoiding complex breakup modes in the diaphragm.

This critical material characteristic allows the Wilson Benesch design team to achieve mechanically and acoustically what would otherwise be implemented in complex crossover designs with a series of inductors and capacitors. This reductive approach to crossover design maintains phase, linearity and the degree of control over manufacturing and design of both the drive unit specifications and the enclosure air volume allows Wilson Benesch to eliminate all crossover components in the midrange drive units of most Fibonacci Series models running the drive unit directly amplifier coupled.

PRECISION CNC MACHINED FOOT

One of the most important principles in structural engineering is loading. All modern buildings are built upon solid foundations. It is the reference point for everything above it, transferring the load of the structure into the ground. Within loudspeaker design, it is crucial to create a stable point from which the drive units can propagate complex and accurate waveforms that we appreciate as music.

The A.C.T. 3Zero foot is constructed from three separate precision CNC machined elements. The design not only houses the powerful Isobaric Drive System, but it also adds mass low in the loudspeaker chassis and provides structural fixing points for 13mm steel ties to fix into. These steel ties run the length of the loudspeaker chassis and tie into the loudspeaker top.

LAMINAR FLOW GUIDE

The A.C.T. 3zero has been designed to blend seamlessly into a traditional British living space. Proportionally the loudspeaker retains a relatively compact form factor. But additional design details can be observed that allow the A.C.T. 3zero to integrate perfectly into both smaller, compact living spaces and larger spaces.

One example is the Laminar Flow Guide installed in the port for the midrange drive unit enclosure. The elegant Laminar Flow Guide has been manufactured in-house using additive 3D printing technology. The flow guide slows air that is pushed out of the port at the rear of the enclosure by the Tactic 3.0 Midrange Drive Unit.

The Laminar Flow Guide reduces the energy of this escaping air, thereby reducing the potential boundary interaction that occurs when the loudspeaker is placed near to the rear wall, such as within smaller listening spaces.

Judge these speakers by hi-fi criteria such as tonal balance, stereo imaging or detail resolution and they ace the test. Judge them on the ability to communicate the emotion in music, and they are similarly successful. Given a suitably talented system, these Wilson Benesch A.C.T. 3Zero are easily among the finest speakers we’ve ever tested.

What HiFi Magazine March, 2023

SPECIFICATIONS

DRIVE TECHNOLOGY | |

Midrange | 170mm(7") Wilson Benesch Tactic 3.0 |

Tweeter | 25mm (1”) Wilson Benesch Fibonacci Hybrid Silk-Carbon Tweeter |

Low Bass | 170mm(7") Wilson Benesch Tactic 3.0 |

Isobaric Drive System 1 | 2x 170mm (7”) Wilson Benesch Tactic in Clamshell Formation |

CROSSOVER TECHNOLOGY | |

Midrange | Directly Amplifier Coupled |

Tweeter | Second-Order, 5kHz High Pass Filter |

Low Bass | First-Order |

Isobaric Drive System 1 | First-Order 500Hz Low Pass Filter |

ENCLOSURE TECHNOLOGY | |

Materials | A.C.T. 3Zero - Advanced Biocomposite Monocoque Technology, Poly-Alloy, Hybridised Construction |

Midrange | Reflex Port Tuned with Laminar Flow Guide |

Tweeter | Labyrinth Sealed Tweeter Backplate |

Low Bass | Infinite Baffle Sealed Enclosure |

Isobaric Enclosure | Infinite Baffle Sealed Enclosure |

MEASUREMENTS | |

Type | 2.5-way |

Impedance | 6 Ohms Nominal / 4 Ohms Minimal |

Sensitivity | 89 dB @ 1-Meter on axis, 2.83V Input |

Frequency Response | 34Hz - 30kHz |

DIMENSIONS & TERMINATIONS | |

Height | 1132mm (44.5") |

Width | 194mm (7.6") Baffle // 276mm (10.8") Widest Point of Foot |

Depth | 376mm (14.8") |

Weight | 48kg (106lbs) |

Termination | Bi-wirable terminal located on the loudspeaker foot at ground level |